| Part No | Figure | lhold (A) | Itrip (A) |

Vmax (V) |

Imax (A) |

Pd typ (W) |

Max. (A) |

Time-to-trip (s) |

R min (Ω) |

R Max (Ω) |

R1 Max (Ω) |

|

| UBF | LR190 | 1 | 1.9 | 3.9 | 15 | 100 | 0.8 | 9.5 | 5.0 | 0.039 | 0.072 | 0.102 |

| UBF | LR190S | 2 | 1.9 | 3.9 | 15 | 100 | 0.8 | 9.5 | 5.0 | 0.039 | 0.072 | 0.102 |

| UBF | LR260 | 1 | 2.6 | 5.8 | 15 | 100 | 1.0 | 13.0 | 5.0 | 0.020 | 0.042 | 0.063 |

| UBF | LR260S | 2 | 2.6 | 5.8 | 15 | 100 | 1.0 | 13.0 | 5.0 | 0.020 | 0.042 | 0.063 |

| UBF | LR380 | 1 | 3.8 | 8.3 | 15 | 100 | 1.2 | 19.0 | 5.0 | 0.013 | 0.026 | 0.037 |

| UBF | LR450 | 1 | 4.5 | 8.9 | 20 | 100 | 1.4 | 22.5 | 5.0 | 0.011 | 0.020 | 0.028 |

| UBF | LR550 | 1 | 5.5 | 10.5 | 20 | 100 | 2.0 | 27.5 | 5.0 | 0.009 | 0.016 | 0.022 |

| UBF | LR600 | 1 | 6.0 | 11.7 | 20 | 100 | 1.7 | 30.0 | 5.0 | 0.007 | 0.014 | 0.019 |

| UBF | LR730 | 1 | 7.3 | 14.1 | 20 | 100 | 1.9 | 30.0 | 5.0 | 0.006 | 0.012 | 0.015 |

| Ihold | Hold current is the maximum current that UB Fuse can pass through without interruption at 20°C unless otherwise specified. |

| Itrip | Trip current is the minimum current that will switch the device from low resistance state to high resistance state at 20°C unless specified. |

| Vmax | The maximum voltage device can withstand without damage at rated current. |

| Imax | The maximum current device can withstand without damage at rated voltage. |

| Pd | The power dissipated from device when in the tripped state at 20°C unless otherwise specified. |

| R min | The minimum resistance of device as received from the factory at 20°C unless otherwise specified. |

| R max | The maximum resistance of device as received from the factory at 20°C unless otherwise specified. |

| R1max | The maximum resistance of device when measured one hour post trip at 20°C unless otherwise specified. |

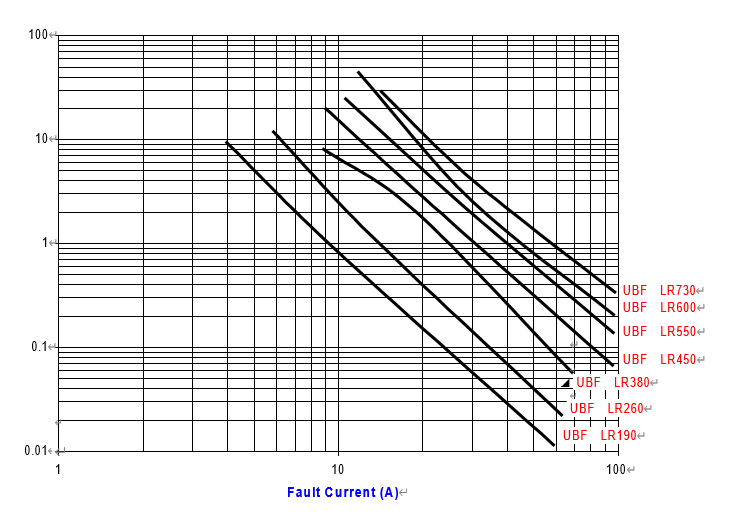

| Max. Time-to-trip |

The maximum time for device to trip at specified current ratings at 20°C unless otherwise specified. |

| Test | Test Conditions | Resistance Change |

| Passive Aging | +70°C, 1000 hours | ±10% typical resistance change |

| Humidity Aging | +85°C, 85% R.H., 7 days | ±10% typical resistance change |

| Thermal Shock | +85°C to -40°C, 10 times MIL-STD-202, Method 107G |

±+5% typical resistance change |

| Vibration | MIL-STD-883C, Condition A | No change |

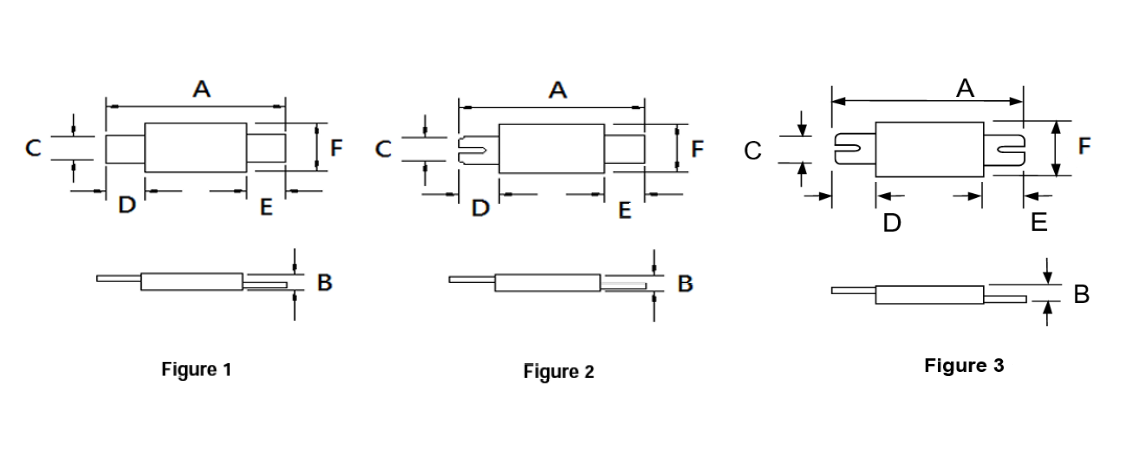

| A | B | C | D | E | F | |||||||

| Part No | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. |

| UBF LR190 | 19.9 | 22.1 | 0.6 | 1.0 | 4.9 | 5.5 | 5.5 | 7.5 | 5.5 | 7.5 | 3.9 | 4.1 |

| UBF LR190S | 19.9 | 22.1 | 0.6 | 1.0 | 4.9 | 5.5 | 5.5 | 7.5 | 5.5 | 7.5 | 3.9 | 4.1 |

| UBF LR260 | 20.9 | 23.1 | 0.6 | 1.0 | 4.9 | 5.5 | 4.1 | 5.5 | 4.1 | 5.5 | 3.9 | 4.1 |

| UBF LR260S | 20.9 | 23.1 | 0.6 | 1.0 | 4.9 | 5.5 | 4.1 | 5.5 | 4.1 | 5.5 | 3.9 | 4.1 |

| UBF LR380 | 24.0 | 26.0 | 0.6 | 1.0 | 6.9 | 7.5 | 4.1 | 5.5 | 4.1 | 5.5 | 4.9 | 5.1 |

| UBF LR450 | 24.0 | 26.0 | 0.6 | 1.0 | 9.9 | 10.5 | 5.3 | 6.7 | 5.3 | 6.7 | 5.9 | 6.1 |

| UBF LR550 | 35.0 | 37.0 | 0.6 | 1.0 | 6.9 | 7.5 | 5.3 | 6.7 | 5.3 | 6.7 | 4.9 | 5.1 |

| UBF LR600 | 24.0 | 26.0 | 0.6 | 1.0 | 13.9 | 14.5 | 4.1 | 5.5 | 4.1 | 5.5 | 5.9 | 6.1 |

| UBF LR730 | 27.1 | 29.1 | 0.6 | 1.0 | 13.9 | 14.5 | 4.1 | 5.5 | 4.1 | 5.5 | 5.9 | 6.1 |

| UL File Number | E 119550 |

| c-UL File Number | E 119550 |

| TUV File Number | Pending |

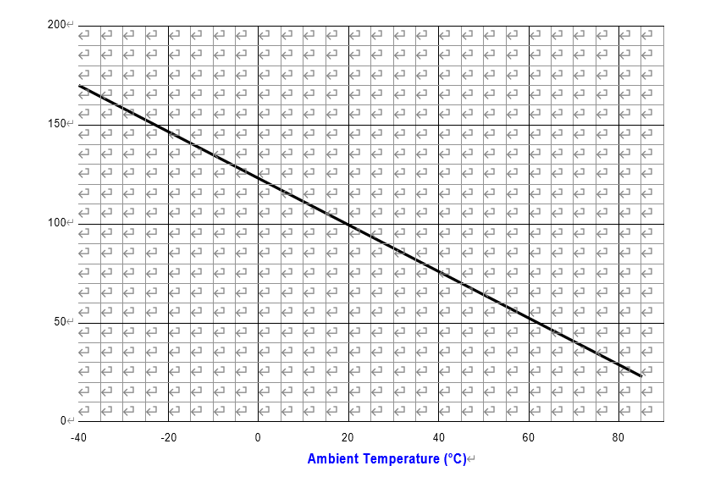

| Part No | -40 | -20 | 0 | 20 | 40 | 60 | 85 |

| UBF LR190 | 2.8 | 2.5 | 2.3 | 1.9 | 1.6 | 1.4 | 1.0 |

| UBF LR190S | 2.8 | 2.5 | 2.3 | 1.9 | 1.6 | 1.4 | 1.0 |

| UBF LR260 | 3.8 | 3.4 | 3.1 | 2.6 | 2.2 | 1.9 | 1.3 |

| UBF LR260S | 3.8 | 3.4 | 3.1 | 2.6 | 2.2 | 1.9 | 1.3 |

| UBF LR380 | 5.4 | 4.9 | 4.4 | 3.8 | 3.3 | 2.8 | 2.1 |

| UBF LR450 | 6.5 | 5.8 | 5.3 | 4.5 | 3.9 | 3.3 | 2.4 |

| UBF LR550 | 7.6 | 6.9 | 6.2 | 5.5 | 4.7 | 4.0 | 3.0 |

| UBF LR600 | 8.7 | 7.8 | 7.1 | 6.0 | 5.2 | 4.4 | 3.2 |

| UBF LR730 | 10.5 | 9.5 | 8.6 | 7.3 | 6.3 | 5.4 | 4.0 |