| Part No | Figure | lhold (A) | Itrip (A) |

Vmax (V) |

Imax (A) |

Pd typ (W) |

Max. (A) |

Time-to-trip (s) |

R min (Ω) |

R ax (Ω) |

R1 Max (Ω) |

|

| UBF | VT110 | 1 | 1.1 | 2.7 | 16 | 100 | 0.7 | 7.0 | 5.0 | 0.038 | 0.070 | 0.140 |

| UBF | VT170 | 1 | 1.7 | 3.4 | 16 | 100 | 1.0 | 8.5 | 3.0 | 0.030 | 0.052 | 0.105 |

| UBF | VT170S | 2 | 1.7 | 3.4 | 16 | 100 | 1.0 | 8.5 | 3.0 | 0.030 | 0.052 | 0.105 |

| UBF | VT175 | 1 | 1.75 | 3.6 | 16 | 100 | 0.8 | 8.75 | 5.0 | 0.029 | 0.051 | 0.102 |

| UBF | VT175N | 1 | 1.75 | 3.5 | 12 | 100 | 1.0 | 8.5 | 3.0 | 0.029 | 0.051 | 0.105 |

| UBF | VT200 | 1 | 2.0 | 4.7 | 16 | 100 | 0.9 | 10.0 | 5.0 | 0.022 | 0.039 | 0.078 |

| UBF | VT210 | 1 | 2.1 | 4.7 | 16 | 100 | 1.2 | 10.0 | 5.0 | 0.018 | 0.030 | 0.060 |

| UBF | VT210S | 2 | 2.1 | 4.7 | 16 | 100 | 1.2 | 10.0 | 5.0 | 0.018 | 0.030 | 0.060 |

| UBF | VT210SS | 3 | 2.1 | 4.7 | 16 | 100 | 1.2 | 10.0 | 5.0 | 0.018 | 0.030 | 0.060 |

| UBF | VT210N | 1 | 2.1 | 4.7 | 12 | 100 | 1.2 | 10.0 | 5.0 | 0.018 | 0.030 | 0.060 |

| UBF | VT240 | 1 | 2.4 | 5.9 | 16 | 100 | 1.0 | 12.0 | 5.0 | 0.014 | 0.026 | 0.052 |

| Ihold | Hold current is the maximum current that UB Fuse can pass through without interruption at 25°C unless otherwise specified. |

| Itrip | Trip current is the minimum current that will switch the device from low resistance state to high resistance state at 25°C unless specified. |

| Vmax | The maximum voltage device can withstand without damage at rated current. |

| Imax | The maximum current device can withstand without damage at rated voltage. |

| Pd | The power dissipated from device when in the tripped state at 25°C unless otherwise specified. |

| R min | The minimum resistance of device as received from the factory at 25°C unless otherwise specified. |

| R max | The maximum resistance of device as received from the factory at 25°C unless otherwise specified. |

| R1max | The maximum resistance of device when measured one hour post trip at 25°C unless otherwise specified. |

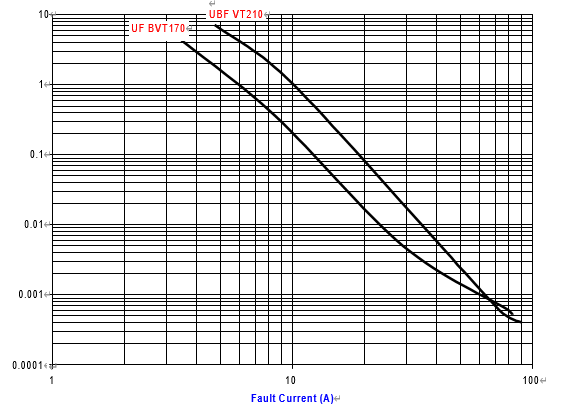

| Max. Time-to-trip |

The maximum time for device to trip at specified current ratings at 25°C unless otherwise specified. |

| Test | Test Conditions | Resistance Change |

| Passive Aging | +60°C, 1000 hours | ±10% typical resistance change |

| Humidity Aging | +85°C, 85% R.H., 7 days | ±10% typical resistance change |

| Thermal Shock | +85°C to -40°C, 10 times MIL-STD-202, Method 107G |

±+5% typical resistance change |

| Vibration | MIL-STD-883C, Condition A | No change |

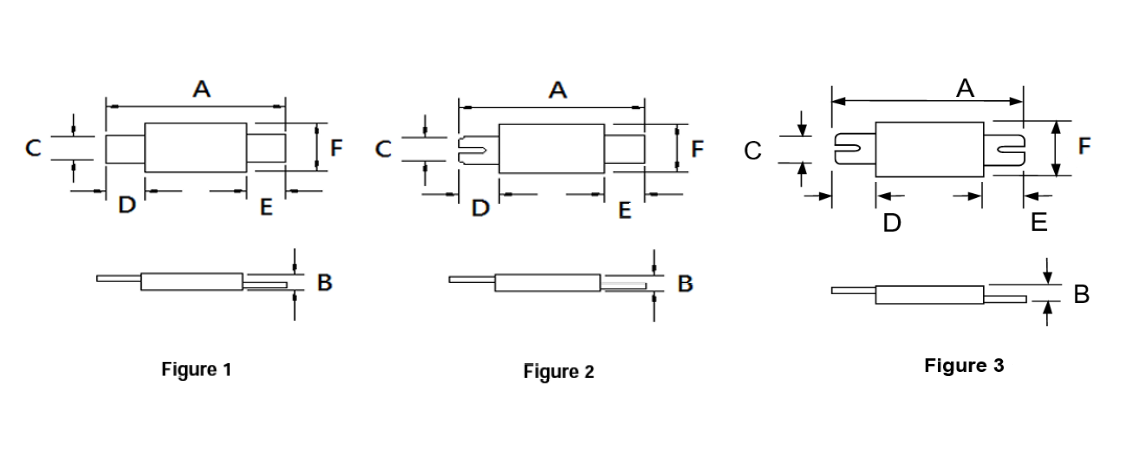

| A | B | C | D | E | F | |||||||

| Part No | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. |

| UBF VT110 | 23.6 | 25.6 | -- | 0.7 | 2.7 | 2.9 | 7.0 | 8.0 | 7.0 | 8.0 | 2.3 | 2.5 |

| UBF VT170 | 15.4 | 17.5 | 0.5 | 0.8 | 7.0 | 7.4 | 4.0 | 6.2 | 4.0 | 6.2 | 3.9 | 4.1 |

| UBF VT170S | 15.4 | 17.5 | 0.5 | 0.8 | 7.0 | 7.4 | 4.0 | 6.2 | 4.0 | 6.2 | 3.9 | 4.1 |

| UBF VT175 | 21.2 | 23.2 | -- | 0.8 | 3.5 | 3.9 | 4.6 | 6.6 | 4.6 | 6.6 | 2.9 | 3.1 |

| UBF VT175N | 26.0 | 28.0 | 0.5 | 0.8 | 3.55 | 3.80 | 6.5 | 8.0 | 6.5 | 8.0 | 2.4 | 2.6 |

| UBF VT200 | 20.9 | 23.1 | -- | 0.8 | 4.1 | 4.5 | 3.0 | 4.8 | 3.0 | 4.8 | 2.9 | 3.1 |

| UBF VT210 | 20.9 | 23.1 | 0.6 | 0.8 | 4.9 | 5.3 | 4.1 | 5.8 | 4.1 | 5.8 | 3.9 | 4.1 |

| UBF VT210S | 20.9 | 23.1 | 0.6 | 0.8 | 4.9 | 5.3 | 4.1 | 5.8 | 4.1 | 5.8 | 3.9 | 4.1 |

| UBF VT210SS | 20.9 | 23.1 | 0.6 | 0.8 | 4.9 | 5.3 | 4.1 | 5.8 | 4.1 | 5.8 | 3.9 | 4.1 |

| UBF VT210N | 30.0 | 32.0 | 0.6 | 0.8 | 3.55 | 3.80 | 5.5 | 7.5 | 5.5 | 7.5 | 2.4 | 2.6 |

| UBF VT240 | 23.8 | 26.2 | -- | 0.8 | 4.9 | 5.3 | 3.5 | 5.7 | 3.5 | 5.7 | 3.9 | 4.1 |

| UL File Number | E 119550 |

| c-UL File Number | E 119550 |

| TUV File Number | Pending |

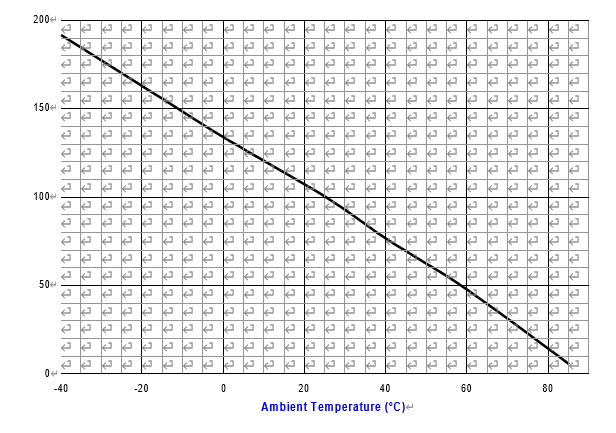

| Part No | -40 | -20 | 0 | 25 | 40 | 60 | 85 |

| UBF VT110 | 2.0 | 1.7 | 1.4 | 1.1 | 0.8 | 0.5 | 0.1 |

| UBF VT170 | 3.2 | 2.7 | 2.2 | 1.7 | 1.3 | 0.8 | 0.1 |

| UBF VT170S | 3.2 | 2.7 | 2.2 | 1.7 | 1.3 | 0.8 | 0.1 |

| UBF VT175 | 3.2 | 2.7 | 2.2 | 1.75 | 1.3 | 0.8 | 0.1 |

| UBF VT175N | 3.2 | 2.7 | 2.2 | 1.75 | 1.3 | 0.8 | 0.1 |

| UBF VT200 | 3.7 | 3.2 | 2.6 | 2.0 | 1.5 | 0.9 | 0.1 |

| UBF VT210 | 4.1 | 3.5 | 2.9 | 2.1 | 1.6 | 1.0 | 0.1 |

| UBF VT210S | 4.1 | 3.5 | 2.9 | 2.1 | 1.6 | 1.0 | 0.1 |

| UBF VT210SS | 4.1 | 3.5 | 2.9 | 2.1 | 1.6 | 1.0 | 0.1 |

| UBF VT210N | 4.1 | 3.5 | 2.9 | 2.1 | 1.6 | 1.0 | 0.1 |

| UBF VT240 | 4.4 | 3.7 | 3.1 | 2.4 | 1.8 | 1.2 | 0.1 |